- ebianchini@creaprogetti.com

- +39 030 2120462

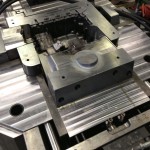

MTM Group guarantees the necessary expertise for all production phases as well as for mould production start. It also can assist customers for maintenance and adaptations works of the moulds.

Operating Machines

The complete and modern machine-park for both departments guarantees the delivery of complete moulds. The need to turn to third companies remains necessary only for the case of thermic treatments of the mould inserts.

Both sectors are able to produce moulds up to 20 tons.

Testing

At the end of production we also assist customers with the sampling, the control and the testing of moulds. Upon customer’s request we also can carry out the 2d/3d dimensional test report of the produced parts.

Maintenance

Upon customer’s request MTM Group carries out also maintenance works for worn moulds. Such works are carried out by our staff inside our workshop. In case of need maintenance works can also be carried out at customer’s site.

Adaptations

In order to guarantee a complete service, MTM Group can also carry out adaptations of the produced moulds when necessary.

Italiano

Italiano  English

English  Deutsch

Deutsch